“A company’s success comes from individual success: involvement, motivation and passion are our top competitive factors”

Mission

The goal of the AGLA Group

The AGLA group works to develop solid and lasting opportunities and relationships with all its stakeholders: whether a customer or an employee, a supplier or a representative of the communities in which we operate, our aim is to build a relationship of mutual trust, based on respect, collaboration and fairness.

We are convinced that a company’s success comes from individual success: our main competitive factors are the involvement, motivation and passion of people, people who can transform the impossible into the possible. This is why AGLA is committed to creating the right conditions for each of our employees to achieve their personal and professional goals and to feel an active and central part of the Group's successes.

Value

comes from values

Value cannot be created without values: the challenges, objectives and results of an industrial group come from its people and not from the organisation of the plant, and AGLA’s story reflects the values of all the people who have helped shape our business idea for over fifty years.

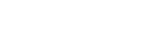

Innovation

Innovation is the trademark of a leading company: that is why innovation is not just an objective for AGLA but is our very raison d’être. Innovation is also widespread, that is, it does not concern a specific corporate department, but every aspect of our work, involving all staff in the continuous improvement of our products, processes and business organisation.

Passion

No competition can be won without passion, the real driver of the people working in AGLA. Every company goal comes from the creativity and motivation of our people, the true stars behind the company’s results.

Determination

Innovation gives direction, passion feeds commitment, but method and organisation are needed to reach a goal. Determination, in this sense, is a proactive, concrete and effective attitude to transform projects into successes.

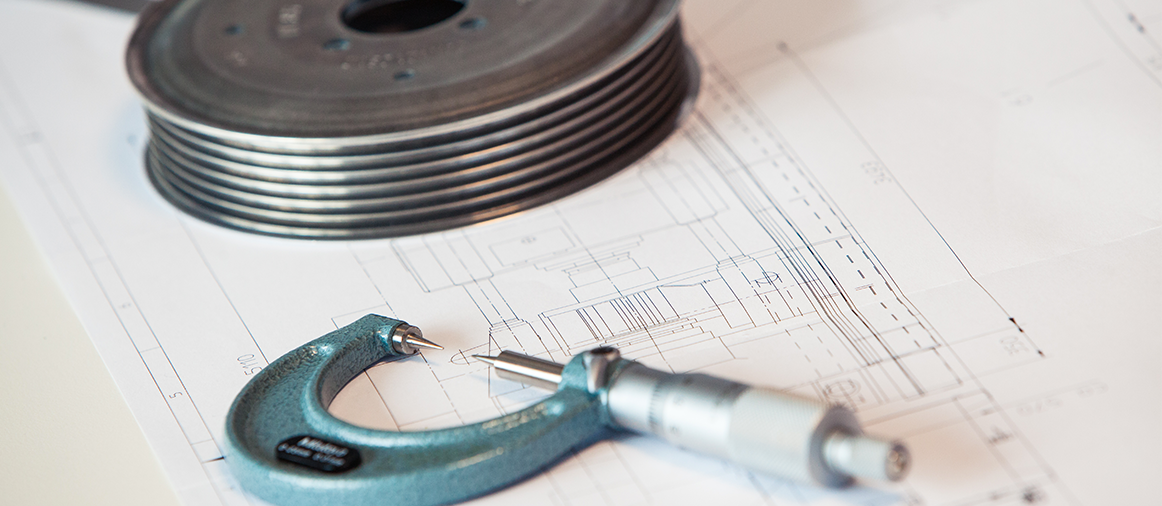

Quality Certifications