AGLA knows

how to do it

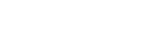

Its technicians’ skills have enabled AGLA to take on major new projects in the field of hybrid petrol engines, with a view to being ready to move into these new engines and away from the diesel engines with which AGLA has a strong and wellestablished history of success.

The secret to the success of AGLA products can be summed up in two simple words: know how, which spans both technological processes and materials. AGLA’s know how does not stop at the concept and design of its products, but extends to the planning and construction of the rolling machines used in production. As regards materials, AGLA does not just work with steel, but also aluminium, rubber (which works in the AEM, EPDM, HNBR compounds) and plastic, which is used to make the new Visco Damper, together with silicone oils.

The AGLA know how

1. Product concept

2. Design

3. Testing

4. Maintenance

5. Tooling and machine development

6. Validation and control

7. Production

The phases of the AGLA process

Make, not buy

The technical office

The beating heart of AGLA’s know how is its Technical Office, a “tech tank” focused on the development of technological solutions dedicated to automatic transmission engines.

From design to prototype, from testing to the definition of the production cycle, the Technical Office works on the four drivers of AGLA innovation: vehicle reliability, reduction of fuel consumption, acoustic comfort and weight reduction, an effort that translates into in ad hoc solutions, because there are no standard products in AGLA.

R&D

The cradle of innovation

Performance on demand is not just a slogan for AGLA, but a categorical imperative that the Research & Development department translates into technological solutions.

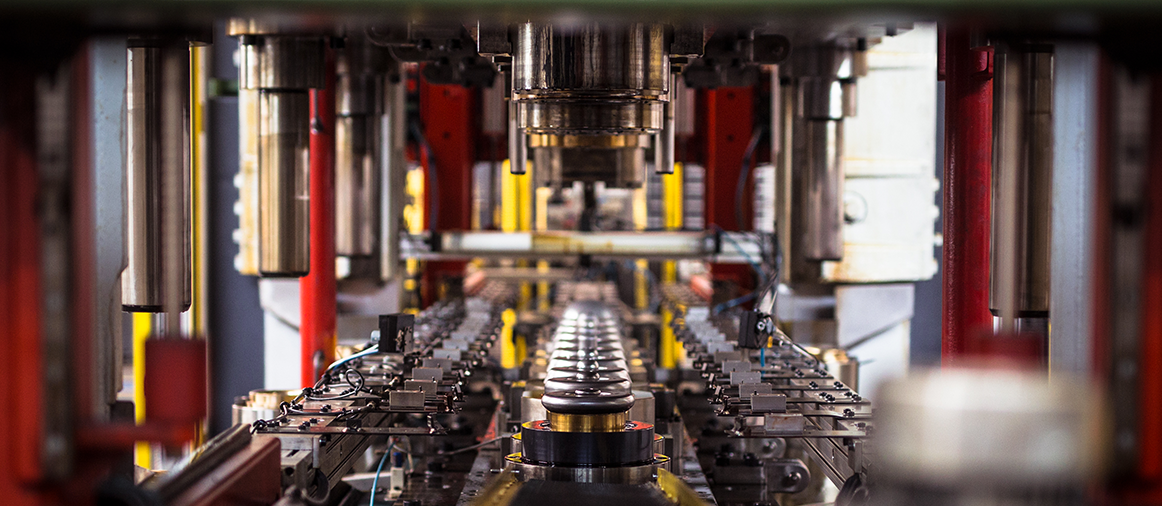

To develop a new product, AGLA engineers and technicians work on innovative solutions for AGLA PT and AGLA FORM customers, starting from co-design with customers, the first step towards the prototyping, testing and industrialisation phases. Co-design is fundamental: in the design of a pulley or a torsion vibration damper, structural calculations, simulations, design and 3D modelling are the tools that guarantee the customer the required performance. Once the design of the product has been approved, AGLA can create a prototype in just a few weeks: a proof of efficiency that is hard to beat in the automotive sector. Subsequently, the product is tested on the customer’s test benches, where performance and durability are measured and functionality is tested: could you ask for a more effective and transparent test? The last phase is industrialisation, where AGLA manufactures “for life” products that meet and exceed the performance required by customers. Moreover, in order to keep its promise of “performance on demand”, AGLA boasts the in-house manufacture of the stamping and rolling tools used in production.

Quality

A 360° commitment

Everyone talks about quality, but for AGLA the concept of quality is a 360° commitment.

Rubber is a key aspect of AGLA innovation, and it is precisely for this reason that checks on rubber components are carried out both on the external surface, with defect checks, and inside, where AGLA can even detect the minimal presence of internal defects through the use of X-rays. It goes without saying that AGLA carries out quality controls also on the parts made of steel and on the whole assembly, where it uses telecentric optical measuring systems to examine all the characteristics of the product, ensuring the customer gets absolute quality. Production checks are also carried out using three-dimensional measuring machines and specific equipment designed and built in-house.

Testing

100% tested

Confident of the quality and performance of its innovation, AGLA is not afraid to test its products on the customer's test bench.

Before arriving at the moment of truth, however, AGLA performs numerous tests and checks, ranging from simulating the behaviour of the belt on the component to the centrifugation test, in the case of pulleys, and frequency response testing for torsional vibration dampers. Lastly, all the materials used are validated through metallographic analyses, tensile tests, viscosity measurements and rheometry. A global control system, aimed at guaranteeing AGLA products in every aspect.